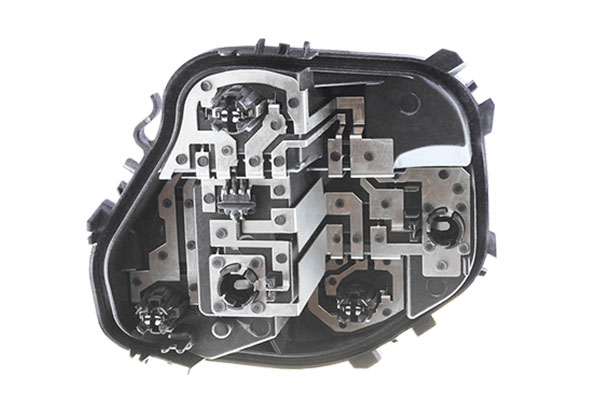

Since the earliest years of our activity, we have pursued the goal to constantly evolve and supply our customer companies with integrated solutions and complete services. In addition to the production of single elements, we have now introduced the production of groups of parts.

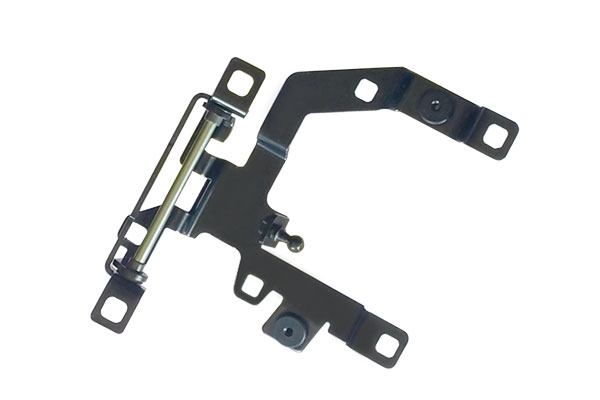

Our assembly department, dedicated to the production of these kinds of groups, uses different technologies both of a mechanical type or by welding (electro welding, laser and TIG).

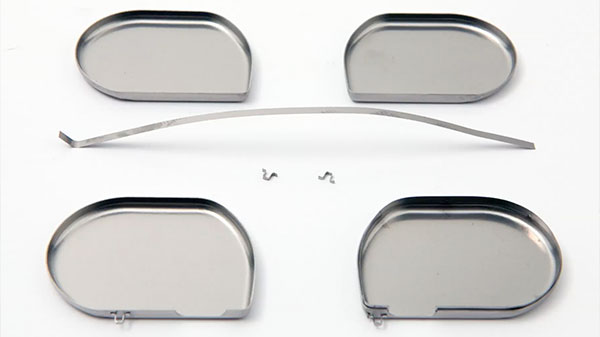

The laser welding department includes 4 working systems with YAG and CO2 sources, continuous and pulsed, to guarantee the process and best results when parts with reduced thicknesses and limited tolerances have to be assembled.

Materials suitable for laser technology are:

Steel

Titan

In the area dedicated to laser welding operations, we also have some welding projection machines and an automated TIG welding system, with which we can perform the assembly of very simple parts.

Finally, in Sacel Group we can also perform the manual assembly of some products. We use this kind of process for less complex parts that do not require a high control and automation level, often to complete more elaborate processes.