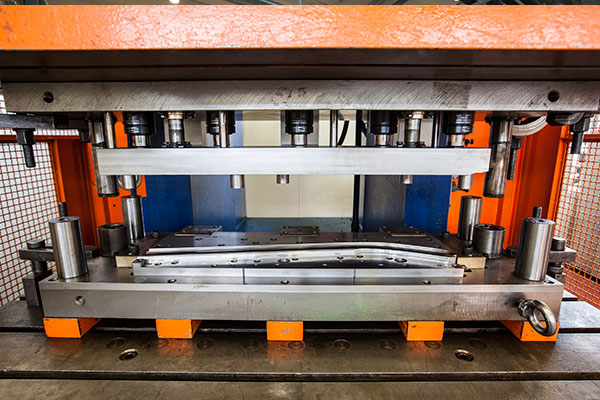

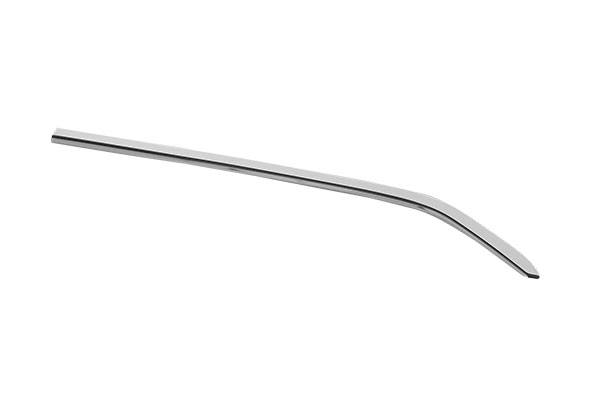

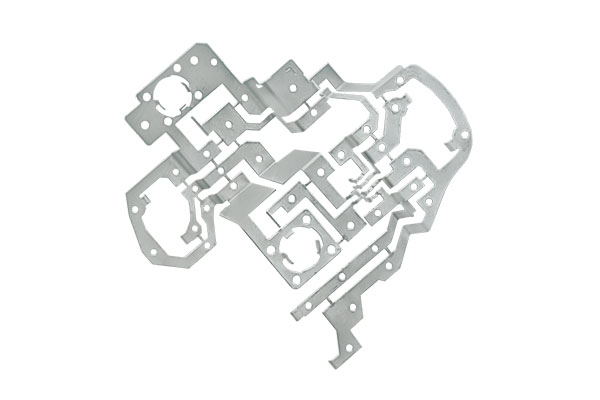

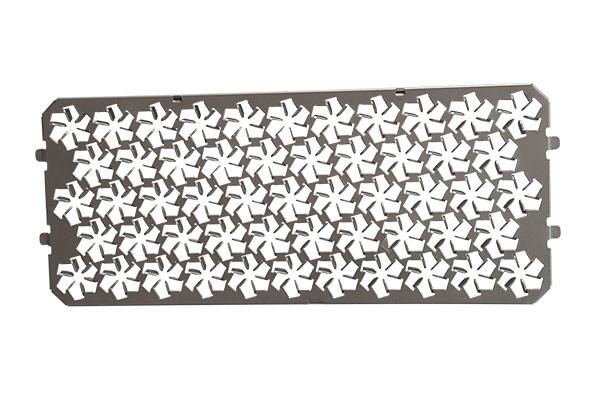

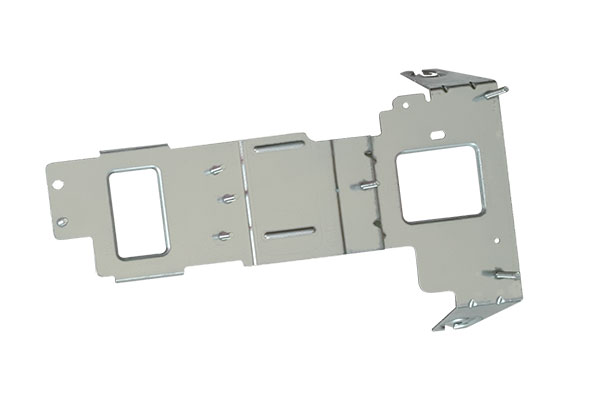

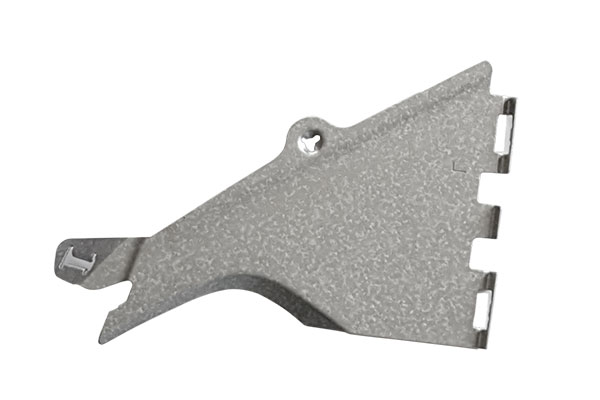

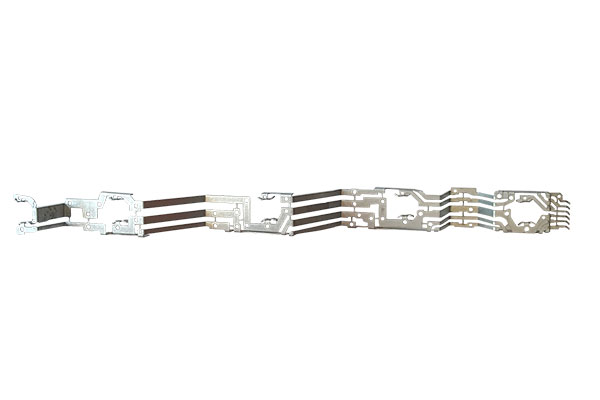

Our metal sheet stamping department includes more than 20 mechanical presses (from 16 up to 630 tons) equipped with automated lines to use progressive dies.

We also have hydraulic and mechanical presses for the simple single stroke metal sheet stamping.

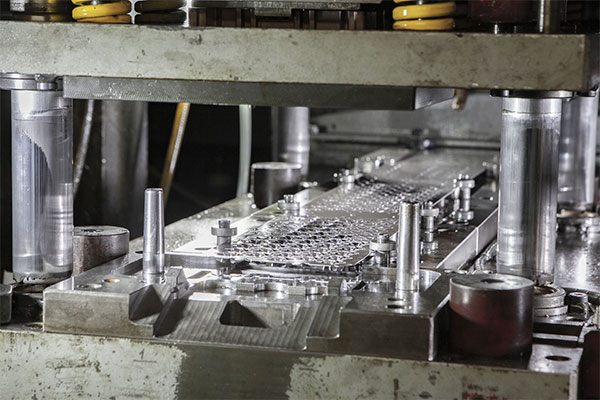

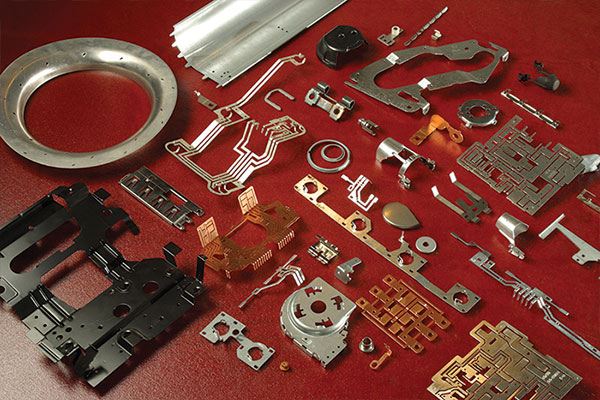

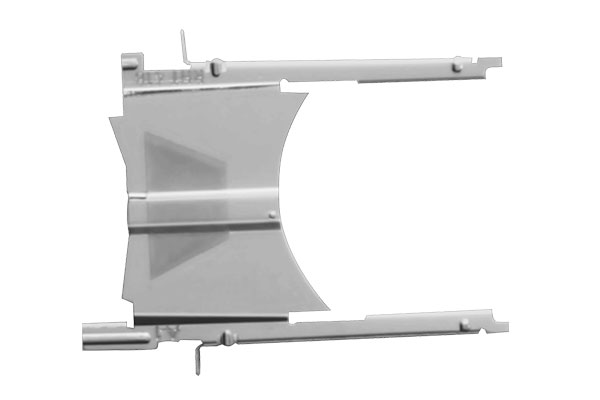

We constantly update our sheet metal stamping processes, which today include all the newest technologies for threading operations, bushing press fitting and small assembly directly on the progressive dies. In this way, we are able to produce quite complex parts with only one stamping operation. Nobody knows plant machineries better than we do; that is why we also take care of progressive die maintenance, an advantage in terms of costs and time that all our partners can benefit from.

In our San Giorgio plant we have a department specifically equipped for ordinary maintenance. Instead, in our Ozegna plant we carry out all the unusual, extra maintenance actions.

OUR METAL SHEET STAMPING CAPABILITIES